The increasing prevalence of noise pollution in urban environments has led to a growing need for effective soundproofing solutions in both residential and commercial settings. According to the World Health Organization, noise is recognized as a significant environmental stressor that can lead to various health issues, including sleep disturbances and cardiovascular diseases. As a result, many individuals and businesses are turning to sound proof foam as an effective means to mitigate unwanted noise, enhance acoustics, and improve overall comfort.

Sound proof foam, designed specifically to absorb sound waves, plays a critical role in noise reduction. Research indicates that properly installed acoustic foam can reduce noise levels by up to 70%, making it an optimal choice for recording studios, home theaters, and offices alike. The effectiveness of sound proof foam is largely determined by its density, thickness, and installation technique. As noise continues to impact our daily lives, understanding how to select and install sound proof foam becomes essential for achieving the ultimate noise reduction and fostering a healthier living or working environment.

When it comes to soundproofing spaces, understanding the types and material properties of soundproof foam is crucial for effective noise reduction. Soundproof foam typically comes in two main types: open-cell and closed-cell. Open-cell foam is lightweight and porous, which allows it to absorb sound waves effectively, making it ideal for reducing echoes in rooms. In contrast, closed-cell foam offers higher density and serves as a barrier to sound, making it more suitable for spaces that require a higher level of noise reduction.

When selecting soundproof foam, consider the material properties that affect its performance. For instance, look for foam that has a high Noise Reduction Coefficient (NRC) rating, which indicates its ability to absorb sound. Additionally, the thickness of the foam can also influence its effectiveness; generally, thicker panels provide better sound absorption. Density is another important factor—higher density foams tend to perform better in blocking airborne noise.

Tips for installation: Ensure the chosen foam is properly cut to fit your space for maximum effectiveness. Utilizing adhesive spray or mounting clips can help secure the panels in place. Moreover, remember to consider the arrangement of these panels; strategic placement can significantly enhance sound absorption in your area.

When selecting the thickness of soundproof foam, one of the primary factors to consider is the type of noise you aim to mitigate.

Thicker foam panels are generally more effective at absorbing lower-frequency sounds, such as bass-heavy music or loud machinery. In contrast, thinner panels may be sufficient for higher-frequency noises like chatter or sharp sounds.

To achieve optimal results, it’s essential to evaluate the specific acoustical needs of your space and the nature of the noise issues you are experiencing.

Another important consideration is the intended placement of the foam panels. The thickness can influence not only the effectiveness of sound absorption but also the overall aesthetic of the environment. For walls and ceilings, thicker foam may offer superior sound reduction, but it may also take up more space, impacting the room's dimensions.

Additionally, if you plan to utilize the foam in smaller areas or for decorative purposes, you might opt for a varying thickness that balances soundproofing with visual appeal. Ultimately, understanding these aspects will lead you to make a more informed decision tailored to your unique circumstances.

When it comes to soundproofing, homeowners often face the choice between DIY methods and hiring professional services. DIY soundproofing can be an appealing option for those looking to save money or take on a project themselves. With the right materials and techniques, such as installing soundproof foam panels, even beginners can significantly reduce noise levels. There are numerous online resources available, including video tutorials and how-to guides, which can help in understanding the best practices for measuring, cutting, and installing the foam effectively. This approach can be particularly rewarding for those who enjoy hands-on projects and have a bit of time to dedicate to their home improvements.

On the other hand, professional soundproofing services offer the advantage of expertise and specialized knowledge. Trained professionals can evaluate your space more accurately and recommend tailored solutions that might include advanced techniques beyond just foam installation. They are equipped with the right tools and have experience with various noise issues, ensuring that the installation not only looks good but is also highly effective. For individuals facing significant noise challenges or those who desire a hassle-free approach, hiring a professional may ultimately save time and guarantee a higher quality of soundproofing. Whether you choose to go the DIY route or hire experts, understanding your needs and the specifics of your space will guide your decision.

When it comes to maximizing noise reduction with soundproof foam panels, strategic placement is crucial. The first step is to identify the primary source of noise and the areas most affected by it. Common high-noise areas include walls adjacent to noisy neighbors, ceilings with loud foot traffic above, or even rooms that echo due to hard surfaces. Using a decibel meter can help pinpoint spots with the highest sound levels, ensuring you target the right locations for foam installation.

Once you've identified these critical areas, consider the layout of your space. Foam panels are most effective when placed at reflection points where sound waves bounce off surfaces. These points typically include the first and second reflection areas on walls, which can usually be found by sitting in the room and having an assistant move a mirror along the wall until you can see the speaker.

Additionally, distributing panels evenly across walls and ceilings can help create a more uniform acoustical environment, reducing overall noise levels significantly. Don't forget about corners—utilizing bass traps in these areas can further enhance sound absorption, significantly reducing low-frequency noise.

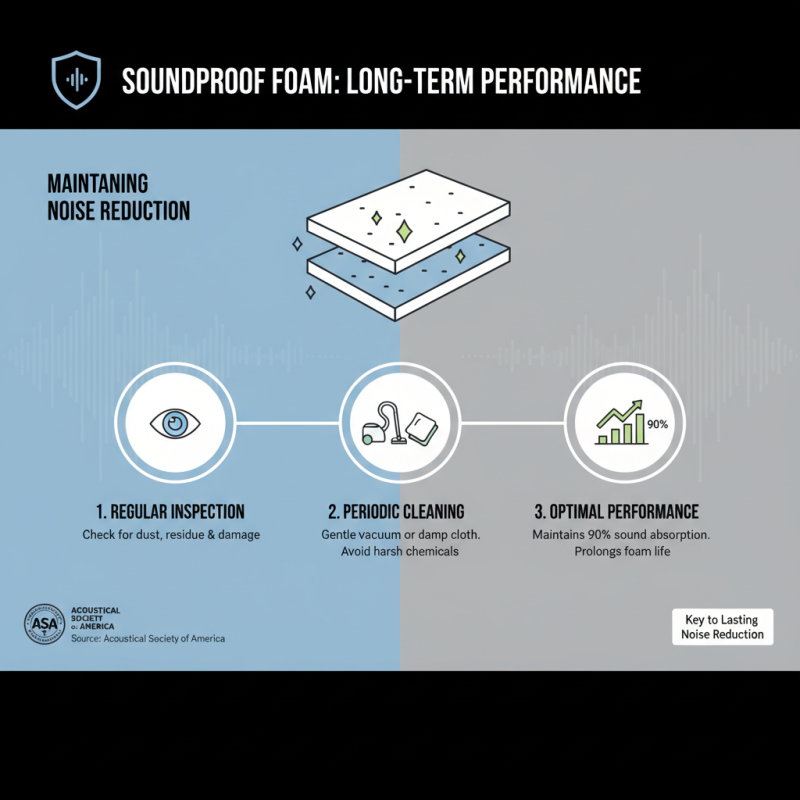

To ensure the effectiveness of soundproof foam over time, proper maintenance is crucial. Research suggests that regular inspection and cleaning can significantly prolong the life of sound-absorbing materials. According to the Acoustical Society of America, proper cleaning can maintain a 90% sound absorption coefficient, which is vital for achieving optimal noise reduction. Dust and residues can accumulate on foam surfaces, leading to deterioration in performance and effectiveness. Utilizing a gentle vacuum or damp cloth to periodically clean these surfaces can help maintain their integrity and functionality.

Additionally, environmental factors play a significant role in the longevity of soundproof foam. High humidity and extreme temperatures can cause foam materials to degrade more rapidly. A study conducted by the National Institute of Standards and Technology (NIST) indicates that exposure to moisture can lead to a loss of up to 40% of the foam's sound-absorbing capabilities. To counteract this, positioning soundproof foam away from direct sunlight or damp areas and ensuring a stable indoor climate can protect the material and enhance its durability. By following these maintenance strategies, users can maximize the soundproofing benefits and ensure that their foam remains effective for years to come.